Used for packaging and electrical.

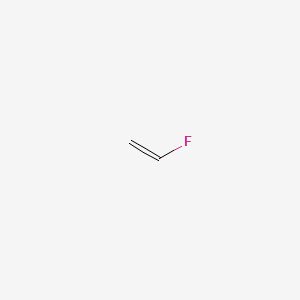

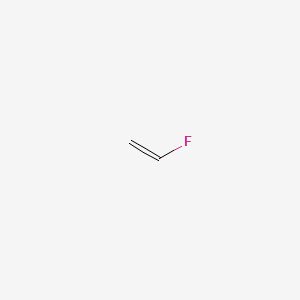

Why vinyl in polyvinyl fluoride.

Looking for polyvinyl flouride.

Poly vinyl fluoride was first introduced in the early 1960s in film form by du pont under the trade name tedlar.

Details of the commercial method of preparing the monomer have not been disclosed but it may be prepared by addition of hydrogen fluoride to acetylene at about 40 c.

X vinyl fluoride polymer.

Polyvinyl fluoride pvf or ch 2 chf n is a polymer material mainly used in the flammability lowering coatings of airplane interiors and photovoltaic module backsheets.

It is structurally very similar to polyvinyl chloride.

At the beginning of t he process vf m ust be stored in high.

Pvdf is a specialty plastic used in applications requiring the highest purity as well as resistance to solvents acids and hydrocarbons.

This book is the first and only handbook that describes polyvinyl fluoride preparation technology processing fabrication and applications making it essential reading for engineers and scientists working in industry sectors where pvf is utilized.

Global polyvinyl fluoride market has been broken down by major regions with complete market estimates on the basis of products applications on a regional basis.

Polyvinyl fluoride is a thermoplastic fluoropolymer with the repeating vinyl fluoride unit.

Polyvinyl fluoride pvf.

A tough transparent plastic resistant to attack by chemicals or by weathering it is commonly manufactured in the form of a film and applied as a protective.

Has superior resistance to weather chemicals oils and stains and has high strength.

In this report the global polyvinyl fluoride market is valued at usd xx million in 2017 and is expected to reach usd xx million by the end of 2025 growing at a cagr of xx between 2017 and 2025.

Polyvinyl fluoride pvf a synthetic resin produced by polymerizing vinyl fluoride ch2 chf under pressure in the presence of catalysts.

It is also used in raincoats and metal sheeting.

In the manufacturing process of pvf converting vinyl fluoride vf into polyvinyl fluoride pvf is the main process and intended result.

Polybutadienes are made either with high cis content 95 to 97 percent or with only 35 percent cis content along with 55 percent trans and 10 percent side vinyl the properties of the two polymers are quite different.

Polyvinylidene fluoride or polyvinylidene difluoride pvdf is a highly non reactive thermoplastic fluoropolymer produced by the polymerization of vinylidene difluoride.

Find out information about polyvinyl flouride.

Compared to other fluoropolymers like polytetrafluoroethylene teflon pvdf has a low.